ABOUT US

Specialist in dosing, mixing and injection machines

With more than 30 years’ experience in dosing, mixing and injection machines, ISOJET EQUIPEMENTS has become one of the leaders in France and in Europe in these technologies and support you in your project to install mono or bi-component resins (PU, Silicone, Epoxy …).

Years of Experience

Units around the world

Turnover

(%) Share of export sales

Countries with an ISOJET machine in operation

(%) Manufacturers of aeronautical resins using ISOJET

ISOJET expertise

Our design department, our technical and sales team put at your disposal all its know-how to help you step by step in the development of your project from the drafting of the specifications to the realization of a tailor-made equipment according to your application and your needs.

ISOJET EQUIPMENTS, thanks to its expertise in dosing and mixing (head with disposable static mixer), you can offer solutions in the following resin applications:

Injection RTM (resin transfer moulding) – Injection RIM – Potting – Encapsulation – Bonding – Casting – Infusion (Vacuum process out of autoclave) – Molding – Composite materials.

MACHINE DPE - ECO

Machine dosing with gear pumps – 2 components – Economical version with limitation on tank capacities – Ideal for small series applications or small castings for RIM injection, RTM injection, Potting, etc.

MACHINE DPE-INDUS

Machine dosing with gear Pumps – 2 components – modular machine with all options – Ideal for big casting applications for RIM injection, RTM injection, Infusion

MACHINE DPE-HV

Machine dosing gear pumps – 2 components for resins with high viscosities and for bonding applications.

MACHINE DPE INDUS FOR BONDING

Machine for gluing / sealing: – 2 components for resins with 1 component with high viscosity and 1 component with low viscosity for sandwich panel gluing applications for the automotive sector (refrigerated truck)

TANK / BATCH UNIT for RTM / RIM injection and infusion (OOA)

System for one component resin or for casting resins already mixed in a mold.

1K - 2K INJECTION & INFUSION MACHINE

A special machine which is composed of a preparation tank and a DPE Indus on the same frame.

INJECTOR PISTON RTM / SQRTM

Piston for injection of one component resin RTM / RIM under pressure 0 to 30 bars.

PRESS

for RTM injection / infusion

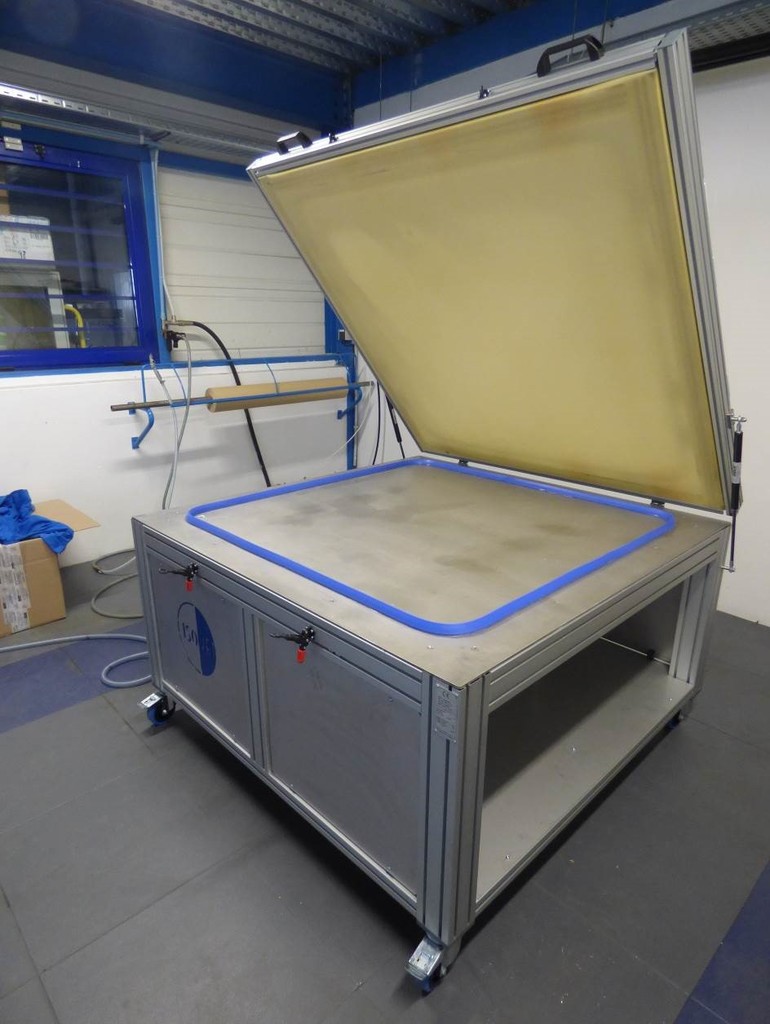

VACUUM TABLE

Vacuum table to allow vacuuming of parts.

Our References

We are present today in many industrial sectors / markets: Aerospace, Automotive, Electronics, Renewable Energy, Prototyping, Maritime and Defense.

Our technology and know-how allow us to be present at many customers such as:

- Airbus Group, IAI, FACC, Embraer, Aerocomposit, KDC , GKN , NLR…

- Lamborghini, Ligier, Aixam, Peugeot, Lamberet, Itron..

- Léoni, Bosch , Syselec , Infaco

- Saft, SunCNIM, E.ITEC, EDF ENR

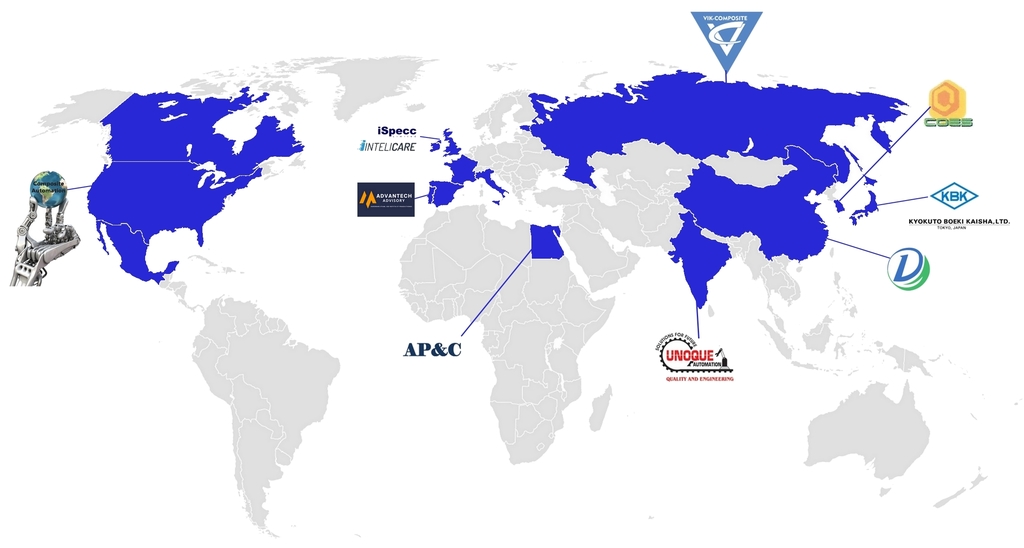

And it’s to strengthen the Relationships with our customers that we have developed internationally.

International locations

UK & Ireland :

INTELICARE– Contact : Philip Jones – Mail : presses@intelicare.co.uk and / or ISPECC – Contact: Nigel Clifford – Mail : nc@ispecc.com

USA : COMPOSITE AUTOMATION : North America : Contact : John MELLILI – Mail : john@compositeautomation.com – Mexique : Contact : Guillermo ALANIS – Mail : guillermo@compositeautomation.com

USA : Marc Rudy Thimon – mail : mr.thimon@gmail.com

Russia : VIK COMPOSITE: Contact : Viktoria RUPPEL- Mail : vr@vik-composite.com

Japan : Kyokuto Boeki Kaisha : Contacts : Akihiko Nogiwa – Mail : nogiwa@kbk.co.jp et Ryota Shitara – Mail : ryota.shitara@kbk.co.jp

China : DUYING C-TECH Co : Contact : Mr. Wang Yunsheng – Mail : duyingco@aliyun.com

Spain / Italy / Portugal Advantech Advisory: Contact : Mr. ANGEL LAGRANA – Mail : angellagrana@advantechadvisory.com

Korea COES – Contact : Mr. LIM DS – Mail : coeslim@hotmail.com

India : UNOQUE – Contact : Mr. Umesh INGOLE – Mail : unoque.automation@gmail.com

Specific Partnerships

CORIMATEC

CORIMATEC is specialized in manufacturing of parts by electroforming and in manufacturing Composite lay-up tools and « Mosites » silicone tools.

SAT THERMIQUE

The leading European company for forced hot air convection heating equipment at temperatures up to 750 °C.Turnkey heat treatment lines: industrial furnaces, ovens and tunnels.

Contact us

A quick and personalized response to your needs

Our experts are at your service.