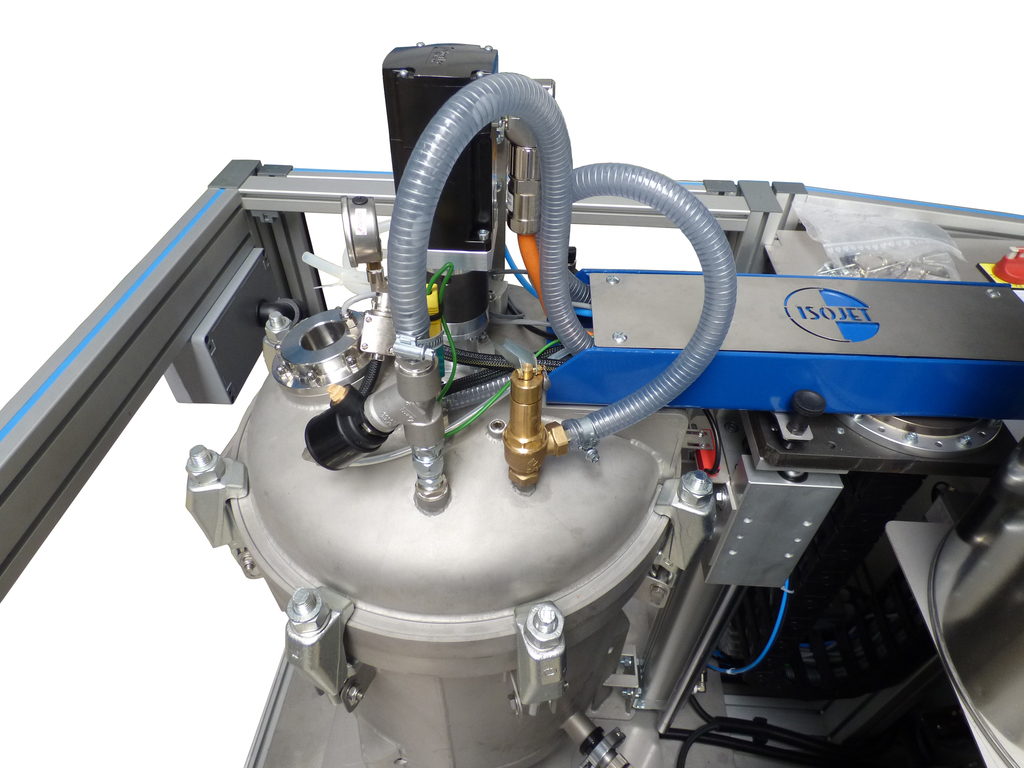

INFUSION & VARTM TANK

Our injection tank is a machine allowing RTM injection (Resin transfer moulding), Infusion, VARTM (Vacuum assisted resin transfer molding) and CAPRI – Controlled Atmospheric Pressure Resin Infusion of a one-component resin or a mixture in a mould.

With our tanks / batches, we have experience with the following resins:

- HEXCEL : HexFLow® RTM 6, HexFLow® RTM230ST, HexFLow® RTM 250ST, HexFLow® RTM 6-2, HiFLow® HF610 FS, HiFLow® 1078-1

- SOLVAY CYTEC : PRISM EP 2400, PRISM EP 2410 and PR 520

- WESTLAKE : EPIKOTE®

Allowing stirring, heating and degassing of the resin prior to its implementation, it also offers a high level of control of the measured and recorded values.Moreover, if you need a large injection pressure, this injection tank can be coupled to an injector piston.

You think our injection tank could be adapted to your application?

Contact us by mail with the form at the bottom of the page and discover the possibilities of our machines adaptable to your application!

CHARACTERISTICS

- Tank volume 1L to 50L

- Resins processed : EPOXY / BMI

- Working temperature up to 150°C

- RTM / Infusion /CAPRI / VaRTM compatible

- Power supply 230V / 400V

- Max injection pressure : 3 bars / 10 bars

- Monitoring : Schneider Citect / SQL

- Automatic up/down system for tank’s lid

OPTIONS

- Vacuum regulation (tank, mould ..)

- Vacuum regulation tank & mould – CAPRI- Controlled Atmospheric Pressure Resin Infusion

- Pressure up to : 25 bars

- Working temperature up to 300°C

- Use custome pail or direct loading in the tank

- Possibility to manage automatically the filling

- Automatic up/down system for tank’s lid

- Editing recipes

- Change of unity

- Languages other than English or French.

- Additional heating hoses

- Pinch valve out of mould

- Extension of thermo-couples number

- Second vacuum pump

Contact / Quote request

Our experts are at your disposal and will contact you as soon as possible.